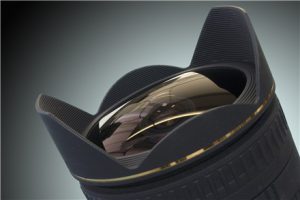

Optically Clear Potting Compounds

Optically clear, low viscosity silicone that offers customers an easy 1:1 mix ratio. This silicone provides a soft, flexible potting compound that won’t put stress on components and will not yellow over time. Great for high temperature (200°C) applications. Offered in TriggerBond™ cartridges.

20-2621

Water clear urethane with excellent environment resistance and low viscosity. This 1:1, non-yellowing compound offers excellent adhesion and flexibility and is a great choice for outdoor applications that will see extended UV exposure or extreme weather. Offered in TriggerBond™ cartridges.

20-3302

Very low viscosity, water clear potting compound. This rigid epoxy offers the highest adhesion and best chemical resistance of the optically clear potting compounds. Easy to work with 2:1 mix ratio cures bubble free and glass smooth. Offered in TriggerBond™ cartridges.

To request a sample of one of these materials, or to ask an expert on which clear product would be best for your application, please fill out Epoxies, Etc.’s Sample Request Form

A major challenge for engineers is finding cost-effective Thermally Conductive Potting Compounds for medium to large potting applications. Many of the commercially available high performance products are not viable options due to the cost that they add to the electronic devices. Also, most potting compounds create too much heat when curing in large mass sizes. 50-2151 FR has a low exothermic reaction temperature. This Polyurethane Potting Compound was formulated to provide a good balance between cost and performance.

A major challenge for engineers is finding cost-effective Thermally Conductive Potting Compounds for medium to large potting applications. Many of the commercially available high performance products are not viable options due to the cost that they add to the electronic devices. Also, most potting compounds create too much heat when curing in large mass sizes. 50-2151 FR has a low exothermic reaction temperature. This Polyurethane Potting Compound was formulated to provide a good balance between cost and performance. Low outgassing Epoxy Adhesives and Epoxy Potting Compounds are sometimes required in aerospace, optical, and electro-optical applications. NASA has set the standard for testing when it comes to outgassing requirements. The two measurements that are used to screen materials are the Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) of the epoxy adhesive.

Low outgassing Epoxy Adhesives and Epoxy Potting Compounds are sometimes required in aerospace, optical, and electro-optical applications. NASA has set the standard for testing when it comes to outgassing requirements. The two measurements that are used to screen materials are the Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) of the epoxy adhesive.

Managing heat in electronic assemblies is a challenge for countless manufacturers. Many assemblies require the use of thermally conductive adhesives. However, finding a thermal epoxy that is easy to use and does not slow down production due to long cure times is difficult. The

Managing heat in electronic assemblies is a challenge for countless manufacturers. Many assemblies require the use of thermally conductive adhesives. However, finding a thermal epoxy that is easy to use and does not slow down production due to long cure times is difficult. The